You can’t eliminate harmful materials, such as polyester, without replacing it with something else. Turning kelp into fiber, that is what we will work with

Our eco-system and the use of kelp

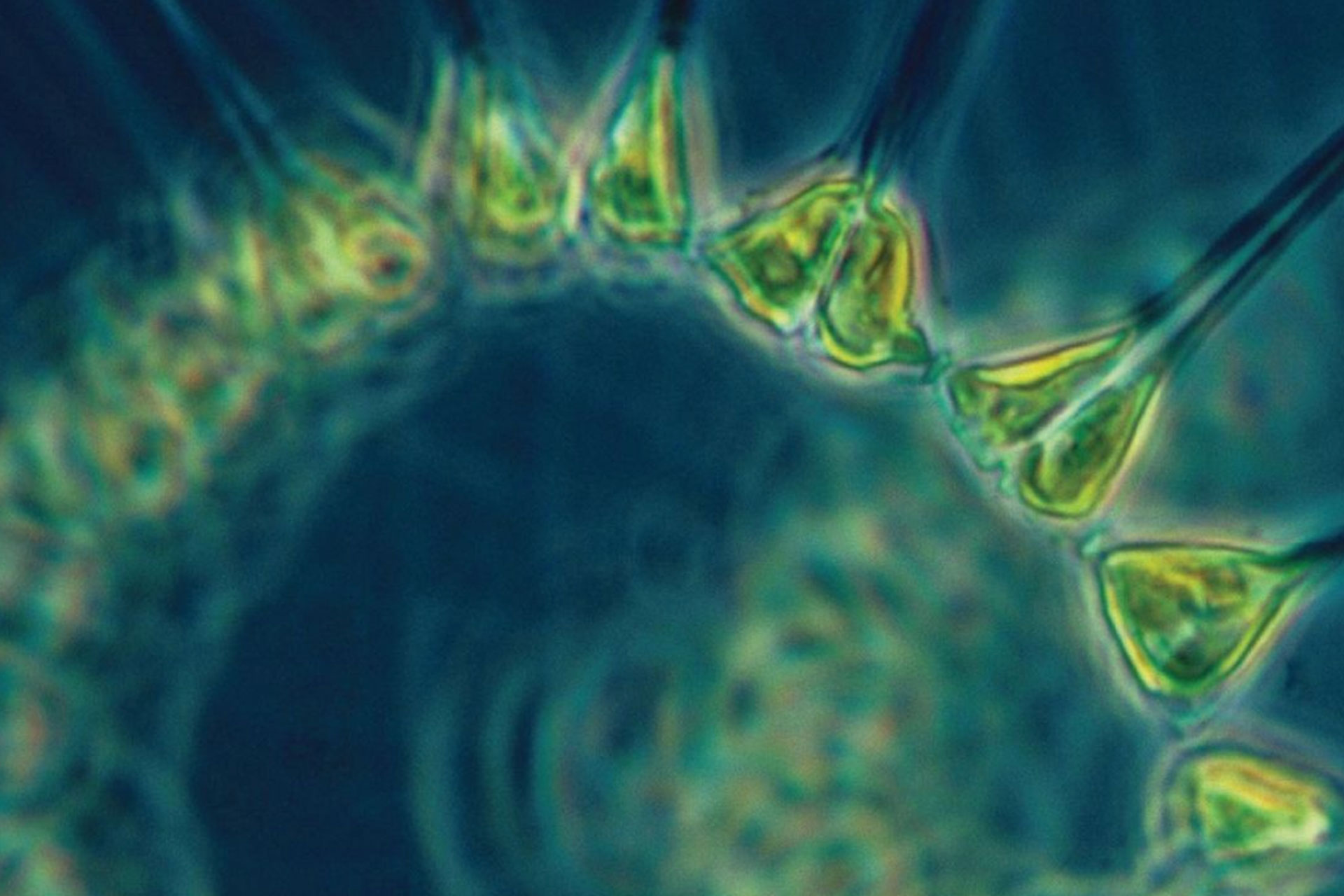

Kelp is relatively large brown algae which grows in vast amounts around shorelines. They help with keeping a steady level of biodiversity as they provide food and shelter for species living underwater. They depend on light for photosynthesis; so they generally grow in areas which have a good amount of nutrients and light. It’s abundant, since they grow entire kelp forests. The giant kelp, for example, can grow between five inches to two feet in one day.

They’re not a very picky species, so harvesting them in appropriate amounts would not harm the quantity of kelp. However, harvesting them the right way is key. For example, many resort to only cutting off the top part of the kelp; leaving the main forest intact for the biodiversity to thrive. As technology evolves, we are finding newer ways to source materials, discovering possible alternatives to create items, such as textiles. AlgiKnit is creating renewable yarn from kelp, following the concept of a circular economy.

Having an impact in the industry that you are part of: AlgiKnit

«We are providing brands, designers and consumers with materials from kelp», explains Co-Founder & Chief Executive Officer, Tessa Callaghan. «This is done by eliminating the toxic processes, present nearly every type of fiber production».

The process of developing this idea came from an industry need rather than out of a lab. Getting to be part of the world of fashion is a competitive opportunity in itself. Finding materials which are innovative, creative and practical all in one, with the added bonus of not having a negative impact on the environment, is a complicated obstacle to go around. In Callaghan’s case as a designer, she was unsatisfied with what was actually available to her.

«We were really struggling because we had this misconception that as designers, we would be able to have an impact on the choices that our company was making around its sustainable practices, particularly around the material choices and supply chains. However, that was not the case.» Either the materials were inaccessible or they were unable to fit in with their production chain. Starting at the end, Callaghan and her team set to find the challenge within the industry itself.

Keeping kelp relevant in supply chains

Keeping in mind how the market realistically is; this type of innovation needs to remain within the bubble of consumer demand. Being creative and eco-friendly is one thing. Completely changing the way in which people understand their role in an over consuming society is another. «The supply chains are not going to change tomorrow», explains Callaghan.

For right now, their focus is on diffusing the idea. Using kelp as a raw material to make fiber and yarn. Again, the issue remains regarding the consumer mindset. Changing too much too fast would disrupt the demand and supply chains; worsening our already damaged economy and complicating the idea of helping the environment. The Algiknit yarn wants to keep it as a «familiar feel»; explains Callaghan, resembling the touch of cotton. Additionally, the natural color of the yarn which comes out of kelp is simply white. This helps it, not only in dyeing situations, but being more widespread in its uses.

One company’s waste stream is another company’s bulk resource

«Our objective is on single-source solutions. Monopolized by both the agricultural and supply resources», explains Callaghan. Shifting these resources into a circular model would help ensure their usage. Not only at different levels of their lifecycle, but throughout various industries which may not necessarily have anything to do with each other.

Take for example the agricultural industry and the fashion industry. For one company’s waste stream of algae, another company can create natural dyes from. Similarly, kelp and seaweed businesses have grown as there have been studies that have found that. Not only are they nutritionally beneficial, but they are helpful in cosmetics as well.

Fitting all these pieces of the puzzle together, another network of supply chains can evolve progressively overtime. The concept is as follows: gradually expanding circular economies over a period of time; to adapt to various industry needs would help develop more ideas; in how to take advantage of resources, every little bit of them.

Keeping the market competitive without harming smaller businesses

Using up resources which already exist is another point which easily translates into a circular economy. The simple definition behind it all is to simply stop using up raw materials; when you have the opportunity, to finish using up others which society labels as ‘waste’.

Callaghan explains that to fit into this ethos, they work with resources which, not only are already inside of a production process, but within an existing supply chain. This ensures that both the resources and the people are not replaced or adding to the competitive landscape. As mentioned before, the kelp and seaweed sector have been rapidly expanding into various industries. There are many manufacturers and suppliers out there who have already established themselves.

Whether that is for harvesting the material, treating it or simply selling it from B2B markets; adding another major competitor would disrupt this system. Incentivizing or even simply giving them more customers; would encourage this industry to thrive under the suppliers who got to it first.

In AlgiKnit’s case, they buy the kelp from an outside manufacture who transforms it into polymers. These manufactures, to the above point, have been supplying various other companies with these polymers for a while. Whether that is for the agricultural, pharmaceutical or cosmetics sector, they are just another brand adding themselves as a customer.

«In house we create a proprietary chemistry. This enables us to implement this new raw material source into an existing fiber manufacturing process», she says. «With that as well, we create a price that works on those manufacturing systems; but also eliminates those toxic chemicals that are widely used throughout». This ensures also that the competitive landscape isn’t touched by disproportionate prices which would otherwise classify the yarn as luxury.

What the future holds: it isn’t a given

Currently, seaweed and kelp can be found in abundance. In some cases it is even a nuisance; as they grow so rapidly that it may be hard to control it. Government initiatives and programs even pay to get rid of them around coastal areas as they don’t smell very nice. In any case, harvesting them at the moment may not be such an issue to ecosystems worldwide. However, as examined before, this particular industry is continuously expanding. Consumers are getting to know the list of benefits which it can have.

Therefore, whether it is five or one hundred years from now; mass harvesting kelp and seaweed may eventually have negative consequences to the environment. Our productivity and consumerism places us in a vicious cycle of using up everything we find useful. We quickly move onto the next raw material until that too, starts running out.

However, Callaghan points out that «it is such a massively available and global resource that, even though it is dramatically expanding now and will continue to do so, even at a large scale as a commercial product, it will not have a significant impact on the industry as a whole». Additionally, although the kelp plant may not grow directly from it, the yarn (or clothing made from it in its purest form) can be put back into the environment to biodegrade.

The concept of biodegradability is relative

«Compared to polyester, everything is rapidly biodegradable». There may be some wondering fears of clothing disappearing out of closets from one day to the next. However that isn’t how biodegradability works. It isn’t until the material reaches a bacterial or fungal rich environment, like composting, that it starts to biodegrade. Recent studies show that AlgiKnit’s yarn gives worms nutrients during composting.

«At worst, we’re neutral», says Callaghan on whether or not biodegrading their material would be harmful to the environment. Having biodegradable properties in a material object could be a requirement in future consumerism. However, it isn’t that simple. Being aware of the economics, logistics and current businesses is just as significant to allow for such innovation to thrive in societies.

The kelp industry has many benefits, and there are many suppliers out there; trying to keep it under a sustainable level. However, it is important that it is kept that way to maintain its current level of circularity. Otherwise it will end up like so much of our supply already has: waste. «For the most part, this is an industry that has showcased. Even too much. Its mass efficiencies in its production process», admits Callaghan.

AlgiKnit

Company developing renewable yarn from kelp to fit within a circular economy. They’re aim is to put fashion inside of a closed-loop product lifecycle. There materials can biodegrade and the resources used are regenerative.