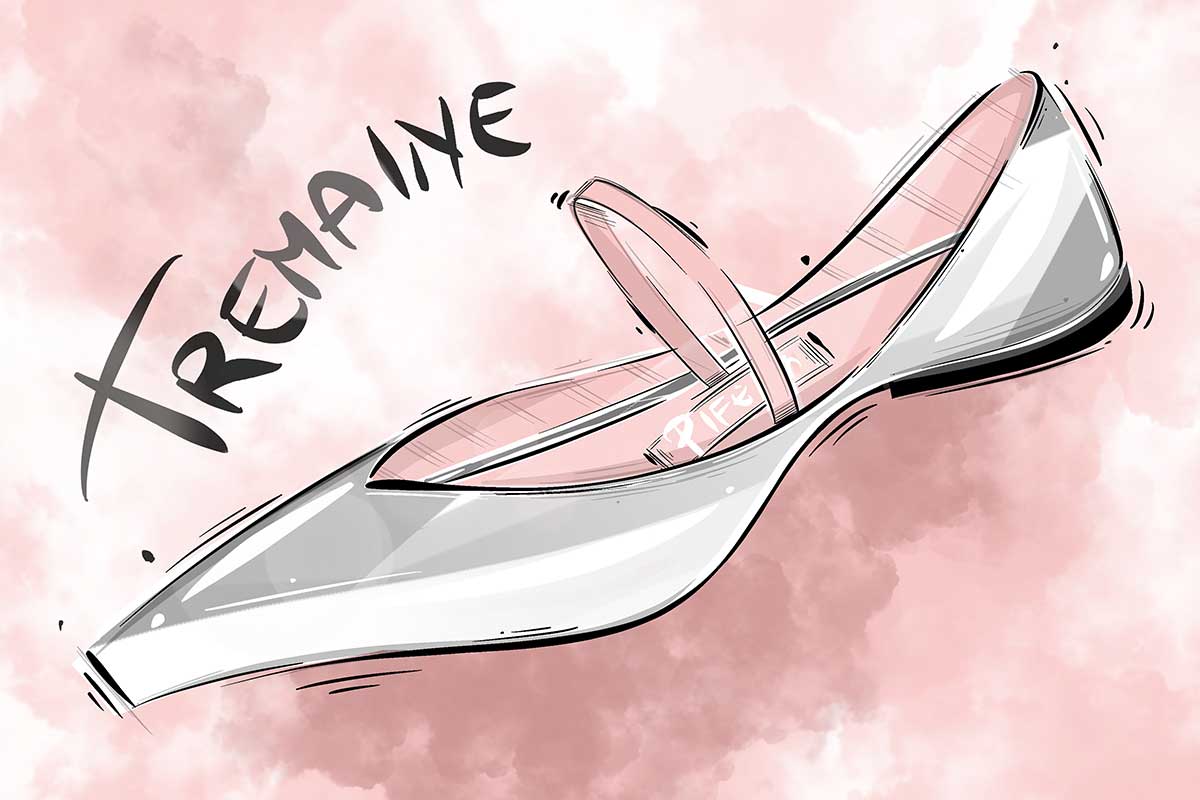

Ethicality as a starting point for the development of a shoe prototype that breaks away from the idea of luxury made through the processing of leather, Piferi project

The choice of creating eco-friendly shoes

The world of clothing and fashion is evolving towards garments that respect a certain ethical approach towards the environment. There are different fabrics created with natural fibers, but the attitude seems to be more problematic when it comes to accessories and shoes in particular. Although some have not even tried to develop or expand towards something different from animal skin, it can be challenging to find materials that are just as resistant and with similar characteristics such as shine or softness. An issue is the lack of being able to use natural or ethical materials which at the same time have the capacity to hold the shoe together, such as being resistant enough to atmospheric agents and daily use.

Alfredo Piferi is an expert in shoe manufacturing and has collaborated with Jimmy Choo, Burberry and Versace. With the aim to make the production of shoes more eco-friendly, he created his brand focusing on each component of the accessory. «I usually don’t talk about sustainability because I find it a huge concept that many brands use in a random way. It’s impossible to promise one hundred percent sustainability when we send shoes by courier and when we are constantly traveling to fashion weeks and development. Talking about a fashion brand we can talk about responsibility in the choice of materials, biomass or recycled for example», states Piferi. The brand was developed starting from a different conception compared to competitors, both in terms of design and values.

The production: the upper material

Although the company is based in London, craftsmanship and manufacturing takes place in Italy to take advantage of local know-how. Regarding the materials used in the production of the shoe, starting with the upper part, Piferi explains: «Our BIOVEG-certified Bio Vegan Nappa is composed of forty-eight percent bio polyols derived from non-food and GMO-free field corn». The final result is that of a plastic material, but not achieved through the use of fossils such as petroleum. In this case, biomass is used instead, extracted in particular from corn and its oil. This accounts for forty-eight percent of the final material to allow for strength, otherwise the material would biodegrade, Piferi continues.

The remaining part of the material is composed of plastic while consciously analyzing the use that the luxury market makes of plastic: «Even in the most renowned brands, at least fifty percent of shoes are composed of plastic. The heel is made of ABS, internal reinforcements are made of plastic, the inner plies are polyester, the dots are made of plastic, even the skins themselves, since animals in nature are not perfect, are covered with a layer of PU to make it homogeneous». The BioVeg material is supplied by the company Coronet, but they do not disclose much information about the actual production. There are currently parts of the shoe that cannot be replaced by materials other than plastic, Piferi claims, such as the heel. To make up for this, the company makes sure to use recycled plastic.

Other components of the shoe

The heels are produced with the use of recycled ABS, in partnership with the Monti heel factory, a pioneer in this type of use of the shoe. «Our heels are crafted from recycled ABS: a recycled plastic compound that is also widely considered more durable, longer-lasting, and easier to recycle than PVC», Piferi explains. Another material used is vegan suede, created using waste from human use, such as plastic bottles, which results in a recycled PET; its characteristics make it a soft product.

«For the soles, thunit material made of fifty percent synthetic rubber, forty percent inorganic mineral compounds (silicones and mixed clay), and ten percent additives (fastenings, pigments) is used, with a luxury finish. It costs less than leather soles and is water resistant, flexible, non-slip and more durable», continues Piferi. The insoles are made of 100% cellulose through a process certified by Forest Stewardship Council, for the proper management of forests in production.

The rubber bang, a distinctive feature of the brand and located at the back of the slingback model, is derived from natural rubber. Another issue to be addressed is that of dyes and adhesives. Piferi explains that in this case, water-based solvent-free ones are used. «Not everyone knows that in the glue, and therefore in the mastic of the shoe, there is animal fat. For this reason research has been done on water-based glue, which is not as resistant, therefore a machine was bought that would extract the water from the glue».

The chemical problem and the performances

Up to thirty-eight percent of plastic material used by the Piferi brand is derived from organic and vegan sources such as oil corn into its collections. In order to increase this percentage, a series of studies have been carried out not only with the brand, but also with chemical experts to try to include this type of material in the production of heels. The results obtained presented a clear limitation to the use of this material: going beyond forty-eight percent of the total material used would result in immediate degradation of the final product.

The study also looked at the material’s ability to sustain maximum and minimum temperatures, and above the stated percentage there would be no more minimum temperatures to keep it from melting. The exposure to the external environment and the demand for resistance for an accessory such as a shoe, do not allow this material to be 100% compostable. As for the performances of the final product, composed of both recycled and natural materials, when compared to a similar luxury product but perhaps composed of leather, they seem to be favorable. Indeed, there are fewer sudden breaks in the most sensitive parts, such as the tips, Piferi explains, as the fabric doesn’t tend to crease. Water resistance is a plus, according to the designer, the rest of the features respect the tests that luxury shoes in general have to pass. All materials are tested by suppliers, one by one, inside the company.

Lampoon reporting: vegan shoes’ status quo

It is understandable the commitment and dedication nowadays to create a responsible type of shoe. However, from what Piferi explains, these creations, like those of other committed brands, are enclosed within this concept of vegan shoes without considering any other attribute. This also devalues the dedication to luxury design and manufacturing, which remain a reserved attribution, in particular when it comes to the use of leather. As Piferi points out, in reality, the luxury price tag cannot be justified only from the point of view of sustainability, but that can represent an additional value.

Regarding manufacturing, it is still complicated to substitute plastics completely with other natural materials, especially considering its resistance and the product performance. For this reason, it is essential to avoid plastics of fossil origin when possible. This can be done by replacing them with natural derivatives such as biomasses. According to Piferi, the benefits of using a vegan material include the possibility of having a roll of fabric that allows to optimize the cutting of the uppers, reducing the waste of the material. It also turns out to be more resistant than leather, especially when it comes to abrasion and water, something which was tested on through resistance tests that also perform on animal skins.

Guaranteeing complete recyclability at the end of a product’s life cycle

As for the expenditure of resources for the entire production process, it is not possible to make a comparison with the traditional methodology because the company does not currently have the means to estimate it. What the brand can declare is that «compared to traditional production methods, the processes used to make our Bio Vegan Nappa have a thirteen percent lighter carbon footprint, use forty-four percent less energy, and reduce by thirty-two percent CFC emissions». No matter how much effort is put into responsible manufacturing, Piferi also explains that one of the difficult aspects to guarantee at the end of a product’s life cycle is complete recyclability, even though all materials taken individually are recyclable.

In the area of footwear, there is no brand that takes the consumed product, divides it into its components and recycles it as a single item. «responsibility starts with the pencil, so the moment you design timeless products, both technically and trendy, that can be used in all seasons and occasions, you’re already taking a step towards that», concludes Piferi. One of the biggest challenges reported in creating products like a responsible shoe is the sourcing of the materials. First, because the amount of material sold in the vegan arena is comparable to that of textiles, but to create a shoe it is necessary to use much less.

Piferi explains that they are often bought at 200 meters per color. Another reason is that this phenomenon occurs whereby large fashion houses, such as Hermes, appropriate entire collections to natural fabrics produced by certain suppliers, not allowing other brands to take advantage of them. In this case, one must wonder about the real will to create eco-friendly alternatives or about the suppliers’ profit-oriented research, but also about the selfish choice of not letting other designers have access to an innovative material.

Piferi

Luxury and designer shoe brand that relies on traditional manufacturing with a responsible approach to the use of materials and the environment. Pīferi were embraced by Harrods Shoe Heaven with an exclusive pop-up in October 2020 and awarded with “Launch of The Year” at the 2020 Footwear News Achievement Awards.