Scientists at Modern Meadow and VitroLabs Inc. have patented a technology that allows to manufacture only needing material using yeast and collagen cells

Modern Meadow on creating leather from yeast and collagen

Bio-fabricating leather starts at a molecular level: they rely on yeast cells that are fermented in a similar way to beer to create collagen, a protein that has long been used in the production of drugs like insulin. Recently, collagen has entered the world of luxury goods. This protein is responsible for giving the hide strength and elasticity, features that make lab-grown leather different from alternative materials made from polymers.

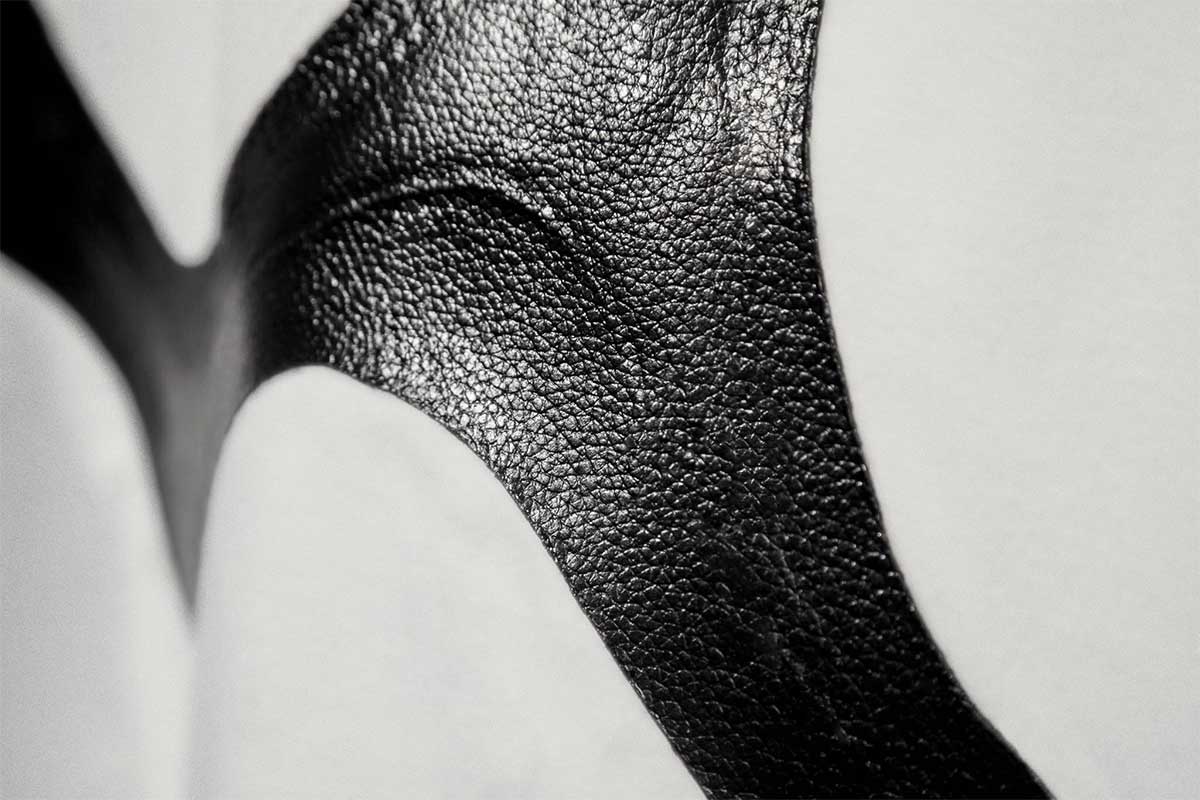

Once the collagen is purified, it can be assembled into material structures and adapted in various ways according to the purpose they were designed for. Modern Meadow is a seventy person start-up from Nutley in New Jersey that started out as a 3D-printed skin developer for medical use. Now they grow animal free leather that has the same structural and aesthetic properties of cow leather, which they call Zoa. The entire creating process of Zoa takes two weeks in total: all the stages of the production happen in a former pharmaceutical laboratory that requires expensive equipment to maintain sterility.

Modern Meadow’s cow leather – Zoa

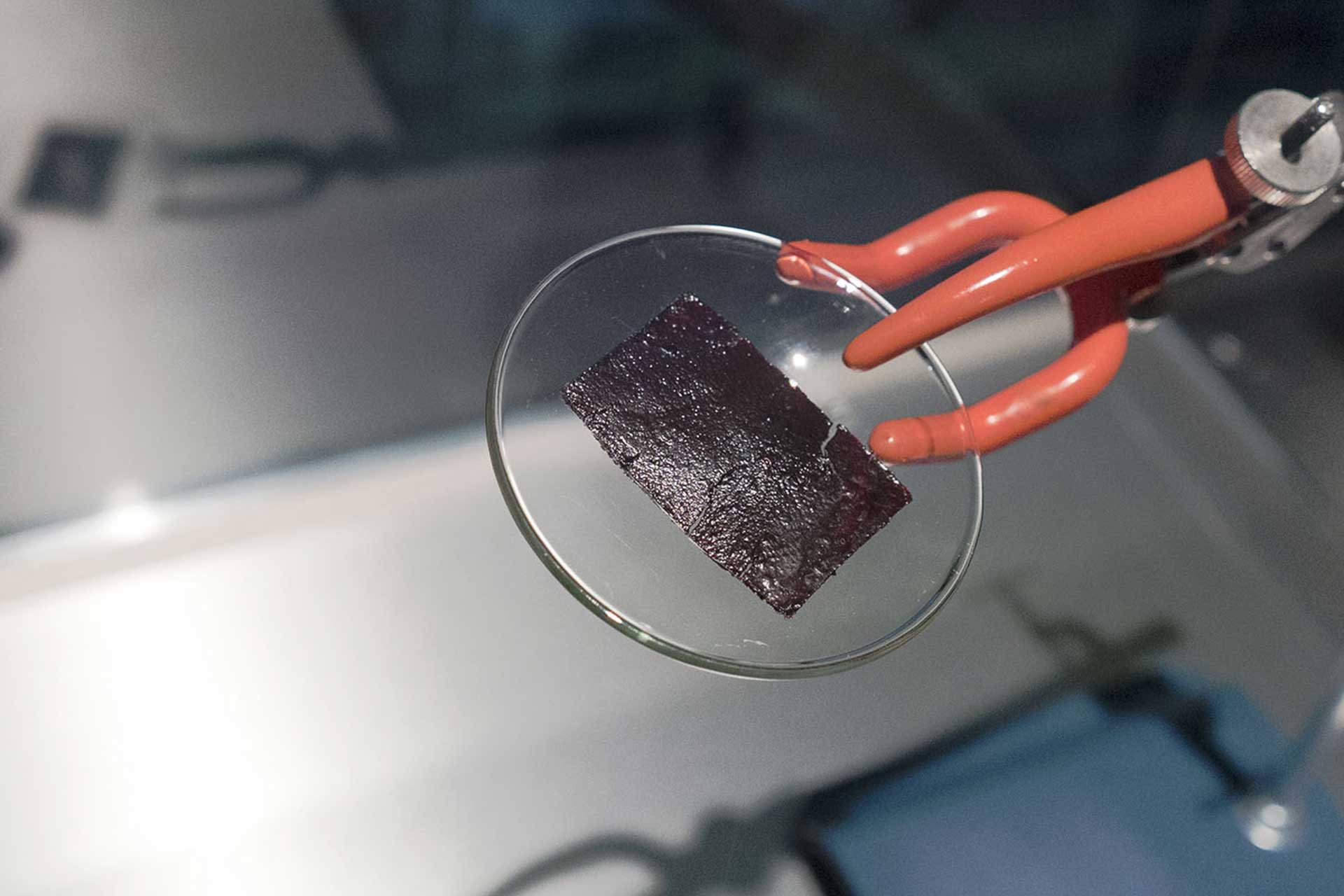

Here, collagen, the main component in this leather, is made. It is done by cultivating and brewing yeast into containers to make it eat sugar and spit out the protein. The leather starts as a liquid, and can be poured into any shape or pattern, or even used as a glue to bond fabric. In order to create sheets of rawhide, Modern Meadow’s team had to add two other genes for enzymes that help modify the collagen’s molecular structure. This could then be harvested and turned into a solid, fibrous material. The goal is to make bio-fabricated leather efficient, high quality and cost effective, so it can be elevated as a competitor of calfskin. Modern Meadow is currently working with more than one-hundred and fifty companies in industries ranging from fashion to automotive, and it is partnering with a leading biochemical company to brew the yeast at industrial scale.

Forging a new material from feeding nutrients to cells: VitroLabs Inc.

VitroLabs Inc. tissue engineering, located in San Francisco, has found a way to create animal hides using a biopsy. By harmlessly extracting cells from a living cow, it is possible to cultivate leather in a laboratory by placing the cells in a nutrient-rich environment that helps them prosper and self-regenerate. Scientists at VitroLabs Inc. use a specialized bioreactor, through which they provide the right signals to the cells to make them grow, divide and form into tissue, without ever going back to the animal. Once the growth phase is complete, the leather undergoes the tanning process.

This is simplified and uses no additional processing, meaning a significant reduction in environmental impact. The whole cultivation phase takes just a few weeks, which is a very short period of time compared to the years of growth of an animal. Yearly production of animal leather consumes circa eighty three billion gallons of water and wastes a total of eighty percent of the animal hide that is left unused. The material grown inside the VitroLabs Inc. bioreactors achieves the same complexity and quality of traditional leather but it is obtained without the waste nor raising and slaughtering of animals.

Can lab-grown leather enter the large-scale market?

The work done by both companies brings to the market a true replacement for high-quality leather. By creating the material in a laboratory, they are rebuilding the supply chain by growing only the leather that’s needed with complete transparency, traceability, and a reduced environmental footprint. Sustainable sourcing has become the foundation of today’s industry, and technology is at service of human commitment when it comes to cutting down the use of limited resources like water and energy. There is no compromise on both consumer or brand sides; the only disadvantage could lie in the price point of the final product. Will the partnering with other companies be enough for developing lab-created leather at a large scale? Will it remain a waste-free production? Lab-cultivated leather is not meant to imitate cow leather, but to reimagine it in a way so it could not depend on the physical limits of the animal. This is not an easy concept to exist in a world where animal agriculture has created vast, untouchable supply chains.

The production of leather from cellular agriculture

On this matter it is safe to say that, beyond avoiding raising livestock, the production of leather from cellular agriculture provides a sustainable alternative to current practices in the leather production process. Stripping animal hide of all the other components besides collagen, is a chemically intensive procedure. Alternatively, the production of collagen directly via cellular agriculture reduces some of the dangers and toxins involved in leather tanning. This is true for both the environment as well as workers in the leather industry, and it has for sure opened up new manufacturing possibilities. A t-shirt made using the new material from Modern Meadow was commissioned and currently displayed to the permanent collection by the Museum of Modern Art in New York as an example of the future of fashion.

The downsides of producing conventional leather

While in the past leather tanning was achieved by soaking it in a concoction of urine, lime and dog excrements to soften and preserve the skin, in modern times things have changed. Nowadays, eighty percent of worldwide produced leather is treated using chromium – a heavy metal that can cause several diseases and is linked to water, soil and air pollution. The consequences of using these caustic substances, results in the production of great amounts of greenhouse gas emissions and deforestation. The rise of veganism is making people demand for leather produced in the most environmentally-friendly way possible.

Leather is often considered a byproduct or waste material created by the industry, while it is a key built-in part of the business model. Its global market is estimated to grow by six percent from 2022 to 2028, reaching over six hundred billion dollars per year. Vegan plant-based alternatives to leather do exist, but some of them are made from polyurethane, a plastic derived from fossil fuels, which of course carries other environmental concerns. While brands are moving away from synthetic materials to make their leather fully compostable and biodegradable, the concept of lab-grown leather developed by scientists is looking to disrupt the fashion industry.

Modern Meadow

Biotechnology company based in Nutley, New Jersey that uses biofabrication to create sustainable materials using proteins. The company was co-founded by Andras Forgacs, Gabor Forgacs, Karoly Jakab and Francoise Marga in 2011 and has since then explored a range of biofabrication technologies. Modern Meadow has gained worldwide recognition after processing the first leather made in laboratory using yeast to create collagen and then assembled into hide.

VitroLabs Inc.

Californian start-up who invented a way to harmlessly grow leather using a biopsy from a living animal. Their technology is able to replicate the molecular structure of leather, combining the latest discoveries in stem cell research, biomaterial and 3D printing.