Reviewing some of the certifications fashion brands are using to claim to be respecting the UN Agenda for Sustainable Development

The rise of certifications in the fashion industry

Final customers are getting informed about the UN Agenda. Customers do not always know how to interpret the symbols of certifications on a brand website or items: they could understand that it means that the brand is seeking to achieve a sustainability standard, but not in what field.

It matters to clarify the difference between each certification that a brand claims to have and what they are certifying since they are meant to be a service for the final client, otherwise, greenwashing will continue to be put into practice. After years of work, in 2015 the United Nations have agreed on reaching certain Sustainable Development Goals (SDGs) for 2030, within the optics of the Global Agenda for Sustainable Development.

The rush to get the certification has been increasing since then

The Agenda set goals that brands, companies, and businesses felt the urgency to reach, and the way to reach them was getting certified. In the fashion industry, the need for certifications emerged since its final customers started noticing researchB about how the fashion world was not respecting the UN objectives. The rush to get the certification has been increasing since then.

A distinction needs to be made between the kinds of certifications applied for, and in, the fashion industry. Some certify supply chains or raw materials, while others, the production process, or production management. Then there are also certifications for business to customer approach, including packaging policies or after-purchasing assistance. Some certifications look at more than one of these aspects or all of them.

Standards and Certifications

Certification standards taken into consideration are 4sustainability, B Corp, and Sustainable Apparel Coalition. While the first one certifies part of the supply chain, the others concentrate on brands’ governance policies. The Process Factory CEo and 4sustainability mark creator, Francesca Rulli, explained that certifications «refer to international standards» to base their validations. 4sustainability®, more specifically, is a trademark certifying the sustainability performances of the fashion & luxury supply chain.

The release and maintenance of the mark depend on the regular verification of KPIs based on an innovative framework aligned to the best methodologies, standards and practices. For example, Planet 4sustainability, one of the six initiatives of the readomap, «is aligned to all ISO standards of the ISO 14001 family, or ISO 50001, or even ISO 14067 for the standards related to the evaluation of environmental systems, up to the ISO on carbon footprint». ISO are technical standards, developed by the International Organization for Standardization (ISO), based in Geneva since 1947.

ISO are standards not born to be certifications

In 2015 standards were revised, bringing betterments and revolutions to the norms in use since the late Eighties. ISO are standards not born to be certifications: they are meant to be a tool for the industry to understand what and where to improve. Besides ISO 14001, used to value the management of the impacts on the environment, a guideline adopted on a global scale is ISO 9001, used to define the requirements for the creation, within an organization, of a Quality Management System (QMS).

In a 2019 report of the best countries for the number of certifications based on ISO 9001, Italy was on the podium, second to China, while the United States was at the ninth place, with five central European countries within the first ten. ISOs are the standard used by certifications for more than one and a half million enterprises every year, growing. «Where there is a global normative reference, if we find a guideline or a certification that already exists and is well done – because there are certifications with a lesser or greater value – we use it», states Rulli. «If, on the other hand, the certification we want, or need, does not exist, or does not convince us, at that point we do research to create our guideline».

B Lab partnership with Global Reporting Initiative Standards (GRI)

B Lab spokesperson, Maria Correa, says that for a part of the certification process they have a partnership with Global Reporting Initiative Standards (GRI), born in Boston in 1997 and shared by the UN in 2002 through its program for the environment (UNEP) to make it a global reference.

GRIs are sustainability reporting parameters, which allow organizations to measure their impact on the environment in a univocal and uniform way, and to make it public in a format that can be understood even by non-experts in the field. This approach considers that the impact of a company is measured from a point of view on the environment, the society, and the economy it involves, and it considers the scale of this impact.

The three pillars of GRI

GRI 200 for the economic aspect, GRI 300 for the environment, and GRI 400 for the social part are the three pillars of GRI. Despite the field of interest of certification, the norm is that the certifying body establishes a set of guidelines that the enterprise must follow if it wishes to be certified. Each certification has its assessment form that an enterprise can fill before demanding to be certified, or that the enterprise can use as a self-grading tool to have an idea of its situation.

Getting certified can become a matter of years, depending on the enterprise size and complexity of the organization. During that time, the certifying body accompanies the to-be-certified enterprise in a journey to improve the weaknesses that emerged in the assessment phase. The journey ends when it is reached a score that can allow the enterprise to be certified.

Lampoon reporting: B Lab assessment certification process

B lab assessment is the B Impact Assessment (BIA). It is formed by four parts: Governance, Workers, Community, and Environment, to which sometimes Customers are also added. Standards are established by an independent multi-stakeholder council composed of experts on sustainable business: the Standards Advisory Council. The certification process follows three steps: Assess, Compare, and Improve. With the first one, the company completes the assessment, then, once obtained the result, it can compare it with other companies.

Results are available online for a consultation to everyone. The idea is that by comparing itself with others, a company is stimulated to improve. B Lab intervenes in practice, on-demand, in the third step, to help the company improve in time, relying on experts, within the company or from other ones – Future FIT business benchmark, or Fair Trade certification, are some of them. It can happen that a company can have a high general score, but in detail, it has a lower score in one part than another.

SEP Jordan helping a community in need in a war zone

In the case of SEP Jordan, focused on helping a community in need in a war zone, the Community score is higher than the media, but the Customers score is much lower. «B Lab has certified more than four thousand companies, between which 140 are in the fashion field». BIA’s questions, from the four parts, have a focus on policy. When asked why, Correa said that «the legal part is crucial because the more businesses grow, they go public, and sell shares to different shareholders that starts to make decisions, often just driven on profit, without taking in consideration the true impact that business is having on the community, on the workers, or on the environment».

Changing a company’s legal structure and documents «makes it accountable to all stakeholders, not just shareholders». It forces a company to rethink its values. «With B Lab we work around the world with B Corporations communities to shape policy – in the United States we have a White House initiative, in the United Kingdom a Better Business act, and in the European Union we are about to launch a policy initiative as well, to try to make it mandatory for businesses to consider the impact of their business decisions on all stakeholders» adds Correa, talking about a process that wants to provoke a system change.

Sustainable Apparel Coalition (SAC)

Sustainable Apparel Coalition relies on its technology partner Higg for the assessment part. SAC’s spokesperson, Sheila Estaniel, explains that the Higg Index «is a suite of tools for the standardized measurement of value chain sustainability. It comprises five core tools based in three key categories: Higg Product Tools, measuring the impact of products we make; Higg Facility Tools – measuring impacts in manufacturing those products; and Higg Brand & Retail Tools – measuring performance of the companies making those products».

The Index is developed by SAC in collaboration with its members. Some of the topics it addresses are water use, carbon emissions, and labor conditions, thanks to which «consumer goods brands, retailers, manufacturers, governments, NGOs, and consumers can inform their individual sustainability strategies and drive collective industry transformation».

Develop a common language for measuring and communicating sustainability performance

Born in 2009 by an idea from Walmart and Patagonia, SAC’s founding idea was to develop a common language for measuring and communicating sustainability performance. «Before we started, everyone had different audits and measurements», says Estaniel. «The SAC spent the last ten years developing standardized measurement tools that help members assess their impact areas. Not only have we enabled our members to measure environmental and social performance in their global supply chain, but as we enter our next decade, members will be able to communicate their organizational and product-level performance to their business partners, stakeholders, and consumers with a framework for verification and Higg Index performance». The Higg Index transparency program was developed to provide the apparel industry with one way to share to the public product-level sustainability performance information.

Process Factory tool of certification: 4sustainability

Process Factory is a service provider specialized in supporting the transformation of business models towards sustainability, focusing on processes, people and tools for continuous improvement. Process Factory is a member of Global Compact, a friend of Textile Exchange and a ZDHC contributor, as well as the first accredited service and training provider for chemical management. It regularly works with international initiatives such as GRI and SAC. 4sustainability is the Process Factory mark certifying the sustainability performances of the fashion supply chain and is based on a framework of six initiatives that companies can implement according to their business priorities: Materials, Chem, Trace, People, Planet, and Recycle.

In June 2021, 167 enterprises were certified 4sustainability, involving a total of over 2000 up-stream suppliers all over the world. Rulli specifies why she wanted to concentrate on the certification of the supply chain: «we wanted to bring out the production processes at the basis of everything. If a brand wants to declare itself sustainable, and then in its reports from the point of view is on lighting or atmospheric emissions, or how much do consume its stores – and it converts the image of its stores – perhaps what is missing is the most important issue: the optimization of logistics. It matters, since 90% of brands do not have production in house, or they have a little part of it». One of the reasons why a brand could decide to get certified is because of a transparency policy that customers worldwide are asking brands to apply. B Lab has been having an increase of thirty percent of assessments a year, in the last three.

Blockchain technology to enhance certification transparency

While certifications are spreading, access to data by customers is not increasing. Within the fashion industry, some operators and brands have started to use blockchain technology to enhance their transparency. Blockchain is a network format created, at the first moment, to keep track of bitcoins transactions. Being based on a decentralized database – meaning that data is saved in more than one location, creating a mechanism to prevent a hacker to corrupt the data or the database itself – some people can have access to this digital ledger to add new information, which will then become part of the chain.

Records of transactions and additions of data are public for everyone who has access to the system. This second kind of access could be possible through the scan of a QR code that will lead to a page, or something similar, in which are stored the links to the different data. In the fashion industry, blockchain technology is a tool that would help the final customer to know who has participated in which stage of an item’s production. Producers, including the raw materials farmers, or designers, and manufacturers, can attach a unique token to the chain while it is forming. Then, through a website or an application, customers can register and see the whole process in detail. In the case of certifications, they would be added to the chain before a product is put up for sale.

A QR code on the label

Customers would then verify their presence through a QR code on the label. «From here to how to communicate to the consumer, each brand makes its own policy» points out Rulli. «There are brands that decide to communicate only upon request, and then provide data from that data collection. There are brands that do not communicate, others that adopt the QR code, but for now they are very few». Using blockchain implies the intent to reach the consumer. «But when you communicate to the consumer you have to get away from technicalities, because we do technical communication from auditing» continues Rulli.

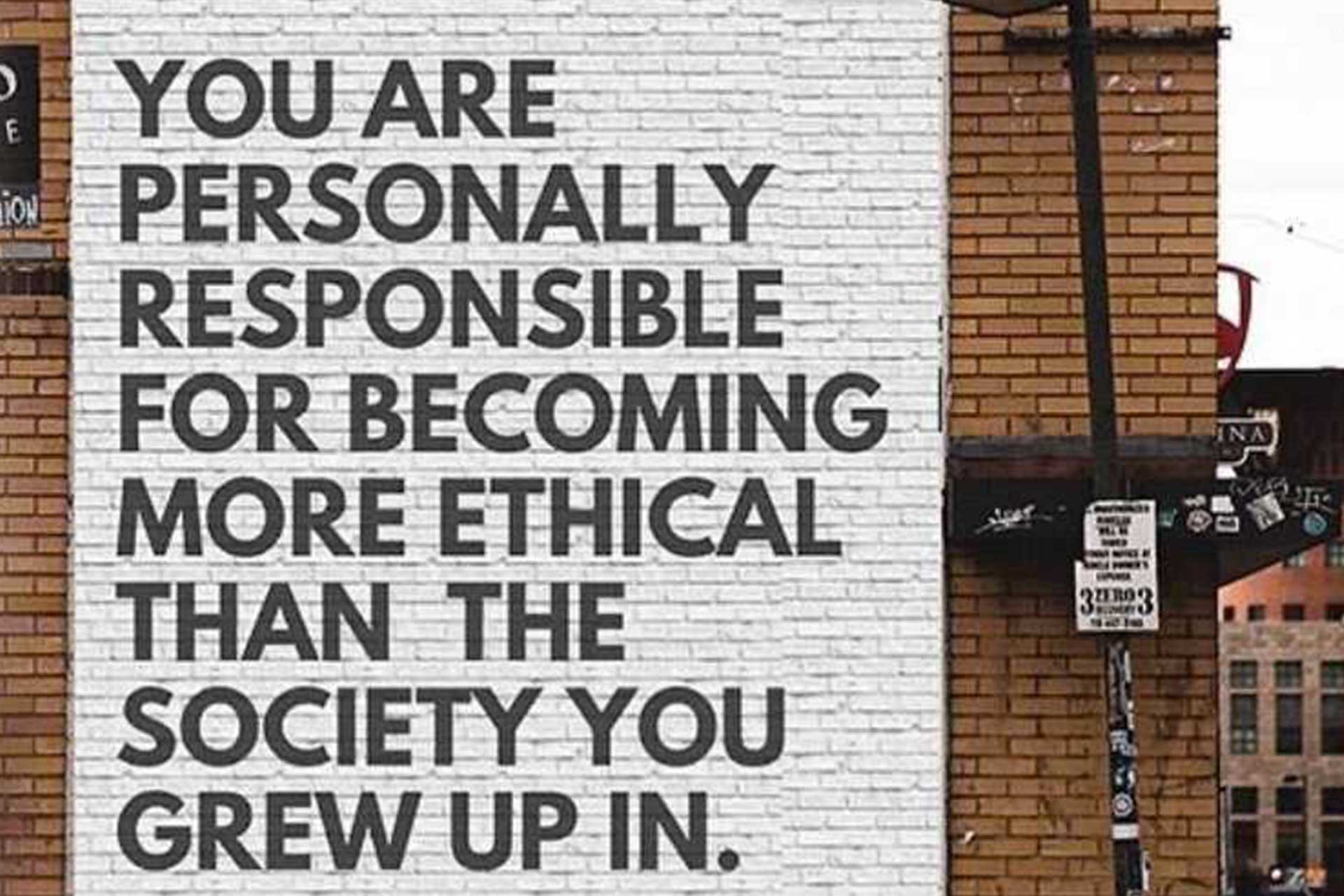

«We need to make a shift in communication, to transform the reports into more synthetic. It is a concept we are working on, implying the issue of controlled supply chain». Certifications are a tool that helps businesses to improve while addressing customers. In the fashion industry, without the need for transparency expressed by brands’ clients, certifications would remain a tool for and understood by technicians. The demand for clarity from customers has been pushing certifying bodies to enhance the comprehension of their reports, causing a betterment of standards levels from which benefits the whole industry.

Process Factory

An Italian company specialized in supporting the transformation of business models into sustainable business models, intervening on processes, people and tools for the continuous improvement of performance. 4sustainability® is the Process Factory trademark that certifies the commitment of fashion & luxury companies to the roadmap for sustainability.

B Lab

Non-profit organization founded in 2006 in Berwyn, Pennsylvania. B Lab created, and awards, the B Laboration certification for for-profit organizations. B stands for beneficial and indicates that the certified organizations voluntarily meet certain standards of transparency, accountability, sustainability, and performance, with an aim to create value for society, not just for traditional stakeholders such as the shareholders.

Sustainable Apparel Coalition

Developer of the Higg Index, self-assessment standard for assessing environmental and social sustainability throughout the supply chain. Founded in 2011, the Sustainable Apparel Coalition is a nonprofit organization whose members include brands producing apparel or footwear; retailers; industry affiliates and trade associations; the U.S. Environmental Protection Agency, academic institutions and environmental nonprofits.